Can I charge my lithium battery with a lead acid charger?

This is a question we get asked every day by the general public. Lithium batteries are not like lead acid and not all battery chargers are the same.

A 12v lithium LiFePO4 battery fully charged to 100% will hold voltage around 13.3-13.4v. Its lead acid cousin will be approx 12.6-12.7v. A lithium battery at 20% capacity will hold voltage around 13V, its lead acid cousin will be approx 11.8v at the same capacity. As you can see, we are playing with a very narrow window of voltage with lithium, less than 0.5V over 80% capacity.

A Lithium LiFePO4 charger is a voltage-limiting device that has similarities to the lead acid system. The differences with Li-ion relate to the higher voltage per cell, tighter voltage tolerances and the absence of trickle or float charge at full charge. Whilst lead acid offers some flexibility in terms of voltage cut off, manufacturers of LiFePO4 cells are very strict on the correct setting because Li-ion cannot accept overcharge. The so-called ‘miracle charger’ that promises to prolong battery life and gain extra capacity with pulses and other gimmicks simply does not exist. LiFePO4 is a “clean” system and only takes what it can absorb.

Lithium chargers are based on a CV/CC (constant voltage/constant current) charge algorithm. The charger limits the amount of current to a pre-set level until the battery reaches a pre-set voltage level. The current then reduces as the battery becomes fully charged. This system allows fast charging without the risk of over-charging and is suitable for Li-ion and other battery types.

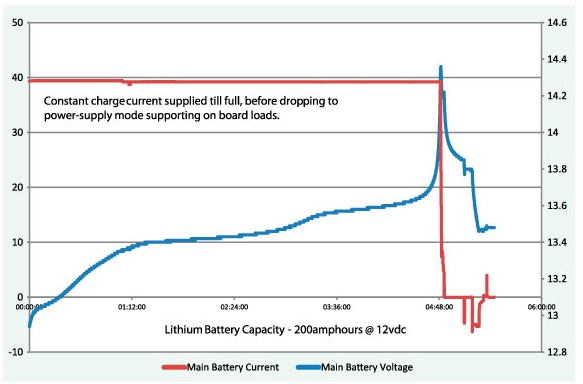

Enerdrive’s ePOWER Lithium Charger Algorithm

As you can see from the above charge graph, the lithium battery has a steep rise in voltage at the very end of the charge cycle. At this stage the charge current drops extremely quickly and the charger then switches to power supply mode.

The majority of the lead acid smart chargers these days have specific charge algorithms to suit Flooded/AGM/Gel batteries which generally require a 3 stage charge process, Bulk/Absorption/Float. Once the charger enters the bulk state, it will normally charge a lead acid battery at full current to approx 80% capacity. At this point the charger will transition to the Absorption stage.

Typical Lead Acid Charger Algorithm

In this charge phase the charger will hold the maximum voltage for the chosen battery and charge the battery with reduced current as the batteries internal resistance can’t accept the charge current at maximum output. Once the current reduces to approx ≤10 % of the chargers total output, it will then move to the float state. The absorption stage is also time based, if the charger is still in its absorption phase after 4 hours, the charger will automatically transition to the float stage. This generally happens if the charger is undersized for the battery bank or there are loads running on the system and not allowing the charger to reduce the current below the transition point.

Most, if not all, lead acid chargers have an equalization mode. On some chargers this mode may be automatic and can’t be turned off. Lithium batteries do not require any form of equalization. Applying an equalization charge of 15v+ to a lithium battery will damage the cells beyond repair.

The other function that lead acid chargers have is a “return to bulk” voltage. A 100% full lead acid battery’s voltage is approx 12.7v. Once the charger is in Float, it will maintain the battery at a pre-set voltage (normally between 13.3-13.8v subject to the battery type) and also support any loads running at the time. If the loads increase past the charger’s maximum output in float, then the battery voltage will start to reduce. Once the voltage reaches the “return to bulk” voltage, the charger will then start a new charge cycle and start re-charging the battery.

The “return to bulk” voltage setting in lead acid chargers is normally 12.5-12.7v. This voltage for a lithium battery is way too low. At this voltage the lithium battery will have been depleted to approx 10-15% state of charge. Lithium charge algorithms will normally set a return to bulk voltage of 13.1-13.2V. Just another reason that a standard lead acid charger doesn’t suit lithium batteries.

Some lead acid chargers “ping” the battery on startup to determine the voltage/resistance of the battery. Based on return information, the charger then determines what charge phase to start in. Because lithium will hold voltage above 13+v, some lead acid chargers will see this as a near full battery and enter into a float stage and bypass the charge stage all together.

You can use a lead acid charger on a lithium battery if you want, HOWEVER, you must NOT use a lead-acid charger if it has an automatic “equalisation mode” which cannot be permanently turned off. A lead-acid charger that can be set to charge no higher than 14.6v can be used for regular charging and then MUST be disconnected after the battery is fully charged. DO NOT leave the lead-acid charger connected to maintain or store the battery, because most will NOT maintain the proper voltage charge algorithm for lithium batteries and damage will occur to the battery that is not covered under battery warranty.

Ultimately, using a battery charger with a specific Lithium charge algorithm is the best option for maximum performance and lifespan of any lithium battery.

SEE BELOW FOR OUR RANGE OF AC CHARGERS, INCLUDING LITHIUM COMPATIBLE CHARGERS:

If you like what you’ve read, you can find even more helpful advice by joining our Enerdrive Unplugged Facebook group! The group is for sharing installations, errors in installations and best practice install guidelines utilising Enerdrive Products across Caravans, Campers and 4WDs. Acting as a space to leave feedback and comments, get inspired and learn from other veteran users along the way!