Cables are integral to your system, but often the weakest link of an electrical install. Read below for the information that will matter most to you:

Table of Contents:

Introduction

Cables, they are the veins, pipes, backbone to your electrical system. Such a simple/no bells and whistles item of your electrical system but one that gets so many questions asked and quite often the weakest link of an electrical install. So, what are some important factors when it comes to cabling? Well, cable selection can be broken down into the below considerations:

- Application (RV/Auto, Marine or Domestic)

- Operating Voltage

- Operating Environment

- Circuit Type (lighting, chargers, inverter, general power for example.)

- Current carrying capacity

- Voltage Drop requirement

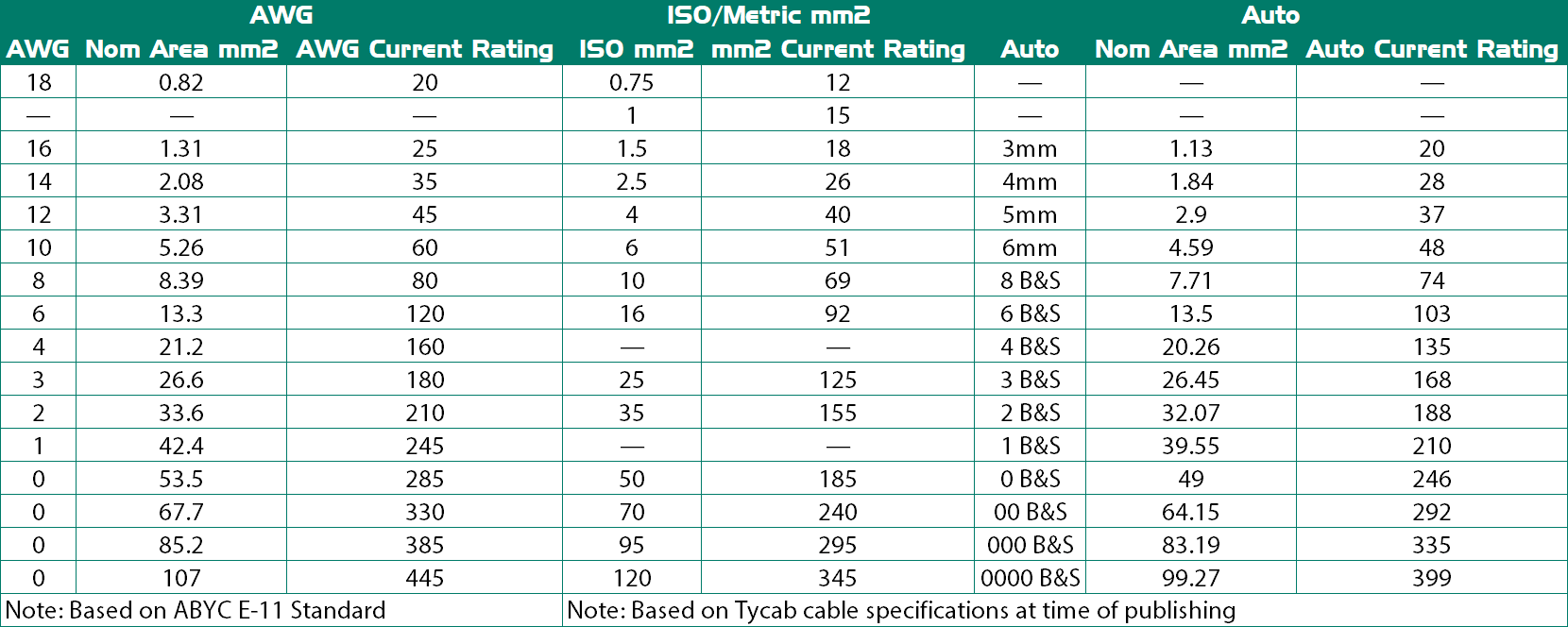

The most confusing part for many is that there are different cable sizing units of measure as follows, American Wire Gauge (AWG), Metric/ISO mm2 and then Auto which is also measured in mm2. The below table shows how these sizes line up against each other along with indication of current carrying rating. I say indication as the current carrying ratings do vary from each manufacturer.

With these considerations in mind let’s look at why they are important and how to use them to select the right cable for each installation.

Application

Looking at the three main applications we are interested in being RV/Auto, Marine and domestic what are the differences and why would you use one over the other. Primarily auto cable being the most used for DC circuits and is usually the best choice. Marine is based on auto cables however is usually tinned (to prevent corrosion) and in some situations also has sheath that is rated against damage by oil and diesel when used in engine rooms. Domestic type cable should be reserved for AC wiring only, and even then, the main consideration when using domestic cables is to avoid single strong cables completely and try to avoid cables with less than 7 strands. Why is this? Simple, a house is not designed to move, so single core cables are fine however in RV’s, 4×4’s and boats the cabling is under consistent vibration and shock which will lead to single core cables weakening to the extent of snapping. Just as importantly the readily available ranges of lugs, crimps and equipment terminations are not designed for single solid core cable. Finally, even though we see it from time to time, wrapping a single core around a screw terminal is not good practise.

Operating Voltage

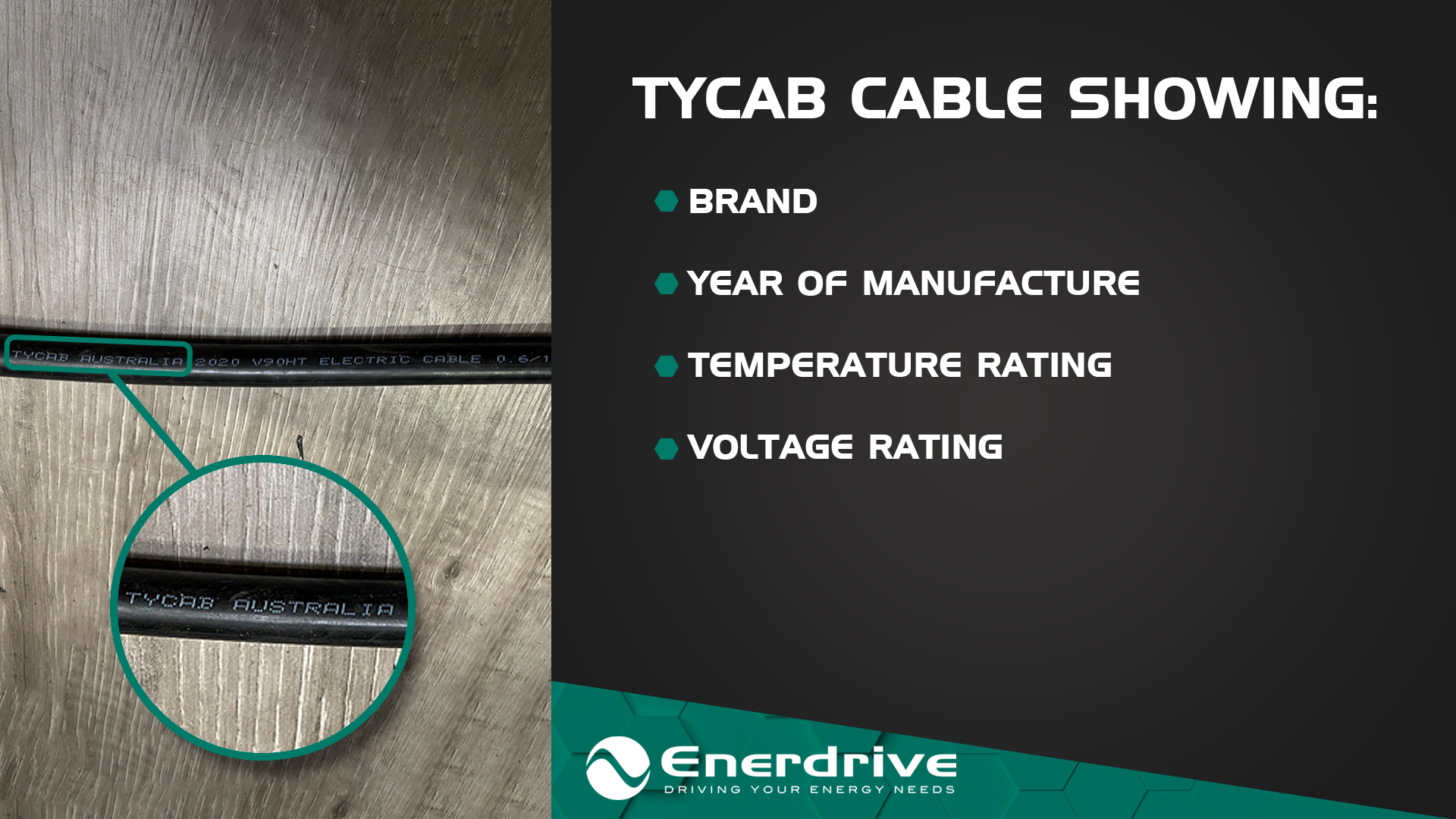

As touched on above, the voltage is key to selecting the cable basic on the physical construction of the conductors but just as importantly the outer sheath is also rated at an operating voltage. This rating is normally seen marked on the cable or label as is usually seen as .6/1kV, what these two numbers relate to is the voltage rating of the insulation to ground (first number) and voltage rating from one insulated conductor to another insulated conductor (second number).

Operating Environment

Insulation not only has a temperature rating, it also has a temperature rating (in Celsius) for its insulation. This is also identified on the cable or product label. The most common ratings seen nowadays are V105 or V95HT, both these ratings are the same and in fact V105 is being replaced by the V95HT rating as V105 is only rated to 95 degrees continuous, the HT meaning HT for restricted periods of time. Again, this is key to check with the manufacturers if your installation will be bordering on those temperature limits.

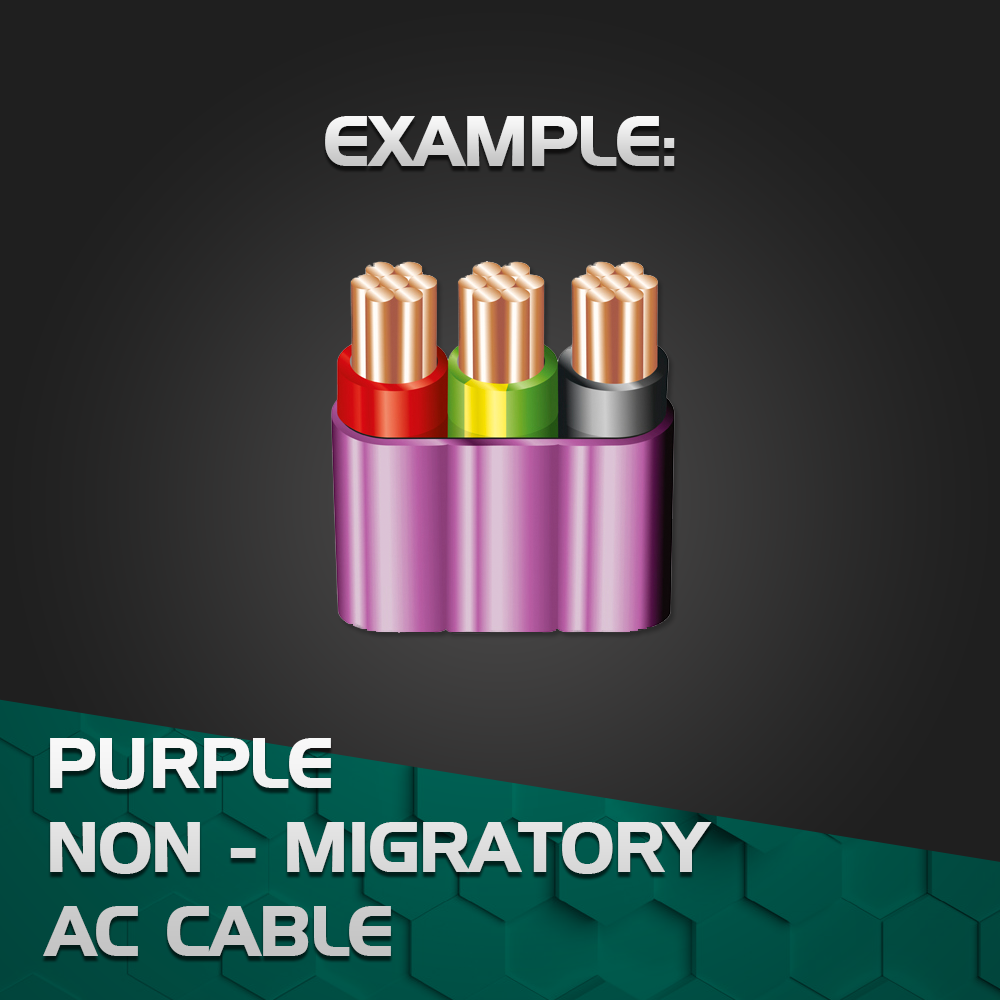

Another consideration, especially in the manufacturing of caravans with composite panelling, is to ensure the cable insulation is rated for contact with polystyrene. Quite often this can be identified in AC cabling by the sheath being purple in colour. This type of sheath is classified as non-migratory and best to be used in cable that are in contact with polystyrene, acrylic, ABS and polycarbonate.

Considerations for the marine environments also include ensuring the sheath is resistant to oil/diesel especially when used in engine rooms. Some standards also call for insulation known as Low Smoke Zero Halogen (LSZH), primarily when installed around accommodation areas. This type of insulation, as the name suggest, emits lower levels of smoke and zero halogens if it is on fire.

Circuit Type

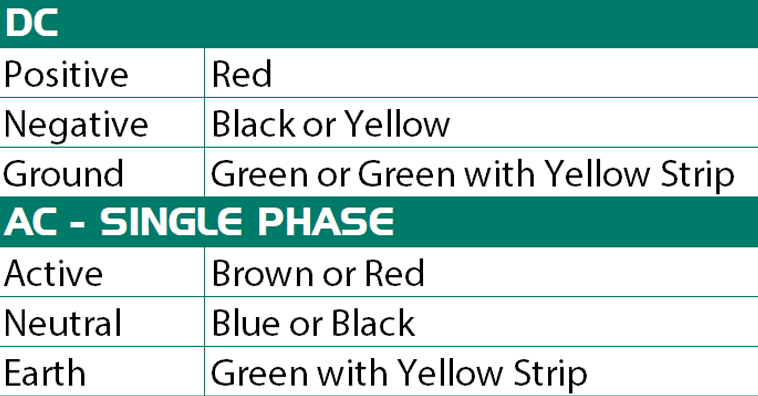

With the key selection criteria covered it is now time to consider the circuit type. The main reason for this is to ensure cable is identified for its use. Below is an overview of the primary cable insulation colours, these must be followed especially when wiring of both AC and DC are in the same installation.

For those that are wondering why yellow is listed as a DC negative colour, this comes from the American Boat and Yacht standards where yellow is preferred due to their AC active conductor colour being black. Although not too applicable here, those that work on boats both imported and locally made will come across this from time to time.

It is quite common with DC cabling, especially with large cables that insulation colour be the same between both positive and negative however identification of its use must be made by means of heat shrink or similar permanent marking at each end of the cable.

Some manufacturers will also follow industry standard or their own standard for identifying DC circuits, this is usually done by colour coded insulation. This method is especially useful when tracing cables along the entire run. Another method of identification is the use of words or numbering at each end of the cable. Although this may make immediate sense when looking at the ends rather than dissevering a colour coding system identifying a single cable in a bundle can prove difficult. Just imagine a bundle of thirty red cables of similar size being cut through by a builder, been there a few times and the old meter gets a workout. The best practise I have seen is the practise of printing the circuit name or numeric code along the entire length of cable, a method that is usually reserved to high end production builders using premade wiring harnesses.

Current Carrying Capacity

Thinking of cables as pipes, the Current Carrying Capacity is like picturing a garden hose trying to pass the same volume of water as a fire hose, it just cannot do it. Like any electrical connection the resistance of the cable restricts the current flow which is why the more current you need to flow (i.e an inverter) the larger the diameter must be.

Always ensure your cables current capacity rating is higher than the circuit protection (fuse or circuit breaker). Maybe obvious, however it is still a common occurrence to see cables melted as they were the weakest link, not the circuit protection. On a side note, circuit protection will not always protect against overheated connections or cables, reason is the fault may be of high enough resistance to create excessive heat but low enough to be below the current required to trip the circuit protection.

Other factors that affect current carrying capacity and need to be taken into consideration in more complex installs include ambient temperatures (engine room/bays) along with how many cables are bundled together.

In relation to ambient temperatures there are no details in the Transportable Structures standard (AS/NZS:3001) however in the Marinas and Boats standard (AS/NZS 3004.2) there is a derating table which shows any temperatures 50 degrees Celsius and above have a derating factor.

For those that are AC licensed you will be aware of AS/NZS 3008 (Selection of Cables for alternating voltages), this standard and the manufacturers specification are what must be followed when selecting AC cables.

Voltage Drop

The last consideration, but extremely important, is voltage drop. This is especially important on main circuit cables such as battery cables, battery chargers (including DC2DC) and inverters. Best practise when selecting cabling for a charger is to have no more that 1% voltage drop (0.12V for a 12V system). Many technical support phone calls we receive is around customers not getting the 40+ Amps from their DC-DC, the cause is almost always due to undersized cables being run from the start battery to the DC-DC, therefore the input voltage being low and the DC2DC derating. In most cases, especially charging circuits, once voltage drop is taken into consideration it is this that determines the cable sizing on chargers, not the current carrying capacity rating.

A great example of this can be viewed on our ‘Enerdrive eTIPS-DC2DC-Cable Size Does Matter!’ Youtube Video:

There are many good resources for voltage drop calculations including the Blue Sea Circuit Wizard circuitwizard.bluesea.com. Along with this all Enerdrive install manuals include cable sizing requirements based on the product and length of run, these must be followed.

Another recommendation I have is ensure your cable comes from reputable suppliers/manufacturers. There are many cable manufacturers here in Australia that produce both DC and AC rated cables in large ranges. The “Infinity” cable recall was one that affected domestic electricians massively and is still ongoing. In this particular recall any house fitted with the cable has required it to be removed and new cable installed. Now imagine doing that on a caravan or large boat!! Buying through a reputable supplier selling well known, locally made cable ensures not only are you getting quality cable, but you will also be better supported if a recall should occur.

And to sum it up this topic is one that you can apply the “Bigger is Better” mentality. Well. OK don’t wire up some LED’s with 70mm2 cable but you get the point!

For a convenient solution to any cabling woes, be sure to check out our range of pre-wired DIY installation kits below. Tailor made for ‘plug and play’ functionality, there is a board to fit every need.

If you like what you’ve read, you can find even more helpful advice by joining our Enerdrive Unplugged Facebook group! The group is for sharing installations, errors in installations and best practice install guidelines utilising Enerdrive Products across Caravans, Campers and 4WDs. Acting as a space to leave feedback and comments, get inspired and learn from other veteran users along the way!